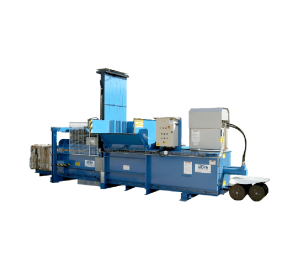

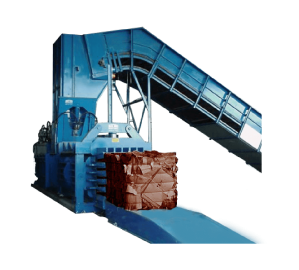

Horizontal balers can be setup to suit an extensive range of site and industry applications. Regardless of systems you may have in place, this solution should be considered for the potential to deliver sizeable operational, financial and environmental benefits for your business.

Showing all 11 results

-

SAPHIR 15

View ProductThe Saphir 15 is compact in size, yet high in output with a compression force of 15 tons and produces bales of between 80 and 150kg. The variable bale length makes this a versatile option for businesses, to suit space and transport requirements.

-

SAPHIR 25 & 40

View ProductThe Saphir 25 and 40 are the entry level to ”Mill Size” baling presses and are the same in size and loading capacity, however have different hydraulic power capabilities, allowing the Saphir 40 to process higher volumes of waste and produce a denser bale, up to 400kg.

-

SAPHIR 300, 340 & 350

View ProductProducing bale weights between 300 and 400kg, the Saphir 300, 340 and 350 produce similar bale sizes but work at varying output capacities ranging from 1 tonne to 5 tonnes per hour, for businesses who need to process faster and more efficiently.

-

SAPHIR 450

View ProductThe Saphir 450 has a large feed opening (1400x1000mm) to suit larger material and is capable of producing bales of between 400 and 600kg, depending on the volume and type of material to be baled and will process up to 2.5 tonnes per hour.

-

SAPHIR 500

View ProductThe most popular of the Saphir balers operating in Europe. The 500 series has an extensive range of designs and configurations. The different models produce bales of between 400 and 600kg, with varying output options to suit actual requirements.

-

SAPHIR 600 & 800

View ProductThe Saphir 600 and 800 are heavy duty fully automatic models that produce bales of between 400 and 800kg, with processing capability of between 8 and 13 tonnes of waste per hour, depending on material density and type

-

SAPHIR 1200

View ProductWith a compression force of 120 tonnes, the larger feed opening of the Saphir 1200 allows for large, bulky and high volumes to be processed with ease, producing finished bales of up to 1000kg.

-

SAPHIR 2000

View ProductThe Saphir 2000 is the largest in the range and is for the very large processing sites requiring high output and produces bales of up to 2000kg, with adjustable size and options include 150 or 200 tonnes.

-

SAPHIR 2050

View ProductThe Saphir 2050 is the smallest fully automatic horizontal balers, has a compression force of 10 tons, and produces bales weighing between 20 and 50kgs. Perfect for businesses who want the efficiency and automation without the large volumes.

-

CHF 25

View ProductThe CHF 25 is a compact closed door semi-automatic horizontal baler and ideal for businesses who may need to process relatively small volumes and/or a variety of different waste types into tightly compressed bales.

-

CHF 1800

View ProductThe CHF 1800 is a closed door semi-automatic horizontal baler and is ideal for businesses who don’t necessarily have a continuous stream of waste being generated, or who need to process a variety of different waste types into tightly compressed bales.

Horizontal Balers – Solution Benefits

- Potential to fully automate systems, improve speed and efficiency of processing recyclable materials

- Ideal to install within your facility to streamline operations, save on space, cut down on labour and reduce mobile equipment traffic

- Compress lightweight products into efficient and saleable bales and create valuable revenue streams for your recyclable products.

- Efficient bales reduce required truck collections each year, contributing to greenhouse gas reductions and lower transportation costs.

- Able to be operated continuously without increases in labour, can be loaded constantly by conveyor, as well as hydraulic bin lifter, mobile equipment and/or manually.

- Recycling saves valuable resources that would otherwise be wasted.

Bringing Recycling Supply Chain Innovation & Best Practice to Australia

In Europe, they take recycling seriously! Whether you are visiting a retail site, a large distribution centre, industrial site or recycling facility, there are two recurring themes discussed when asking why they chose their equipment solutions.

1. Production:

Recycling is a core part of our Production Process within our business, therefore it is essential we select and implement the most efficient solution for our business.

It must consider all aspects involved in handling and consolidating these materials, including safety, labour, space, mobile equipment use, transportation and environmental impact.

2. Maximise Revenue

The sale of recyclable materials we produce is also a core revenue stream for our business, therefore we must endeavour to maximise revenue for our business.

As part of the equipment selection process, the chosen equipment should aim to minimise the collection and handling requirements for our Recycling Partners, enabling higher returns to be received.

Our Approach

At Durogreen we are committed to assisting Australian businesses and their Service partners to transform and improve the way they manage recycling and waste and provide long term sustainable solutions.

Our range of Horizontal Balers, knowledge share from partners in Europe, coupled with our nearly 30 years of extensive industry recycling experience, provides a really unique opportunity to help transform your business operations, improve operational efficiencies, reduce costs and create a new and/or improved revenue stream for your business.

Next steps?

- Are you interested in investigating solutions for your business and not sure what to do next?

- Wanting and/or needing to improve operations, financial and environmental performance?

- Lacking the time, resources and knowledge in this area?

- Not sure if you can really afford new automated solutions?

- Are you producing reasonable volumes of recyclables already?

- Are you currently utilising alternate or old equipment solutions?

You may be surprised with how quickly we can complete a review, what improvements can be achieved and how easy it is to make the change and start to enjoy the benefits.

Contact us today to find out more.

DELIVERY POLICY: Am exerum ab int autemquam aut offic testio cus exerspero et velibus aperiam que veriasimus quas ex et qui tem am volorest, quamus et quaturis ipsae liandi odis quam nonse parcia voluptassum eost, sim quidebi tiasper eiumqui accum facessitiis quatibusae simpossusdae volorem rent