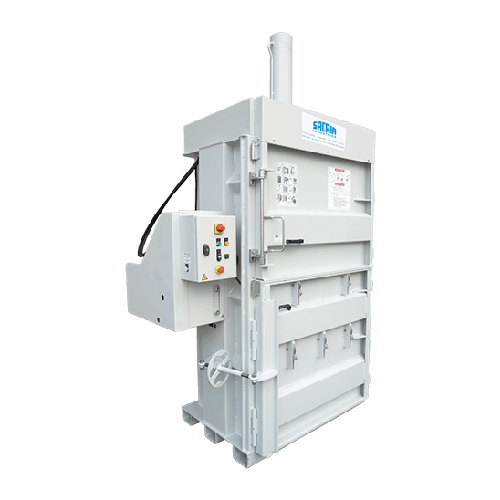

The 500 & 502 vertical balers are the largest in the range and provide two configuration options. Both have a large feed opening and are ideal for businesses processing larger types and volumes of materials.

The bale dimensions are 1300 mm x 1200 mm x 850 (500) and 1200 x 1200 x 850 (502) and deliver storage, handling and transportation supply chain efficiencies for business.

Also included is the unique touchscreen controls for ease of use and easily accommodates large volumes of cardboard, plastic film and other lightweight products of recycling.

The 500 and 502 produces a high density, compact bale of approximately 500kg and 400kg’s respectively and in this format avoid the need for re-baling and enabling a Direct to Mill and/or Return to Distribution Centre logistics model. This creates huge potential for reducing costs and improving overall returns through improved rebates.

Installing a 500 or 502 vertical baler can deliver a big impact for your business. This baler has the potential to create substantial financial, operational and environmental benefits for your business. A few more examples are as follows:

- Large filling opening

- Bale dimension to suit a standard pallet space for storage, handling and supply chain efficiencies

- High compaction force

- Three phase power supply

- Special product retention claws for optimum compression and operation

- Unique and easy to use touch screen controls, with the option to include multiple product selections

- Easy access for strapping replacement

- Low height dual scissor action model available (502)

- Significantly reduce storage space on site

- Significantly reduce frequency of collections, reducing costs

- Create a new or increase an existing revenue stream for your business

- Easily processes cardboard, plastic film and other lightweight and bulky products into an efficient baled format