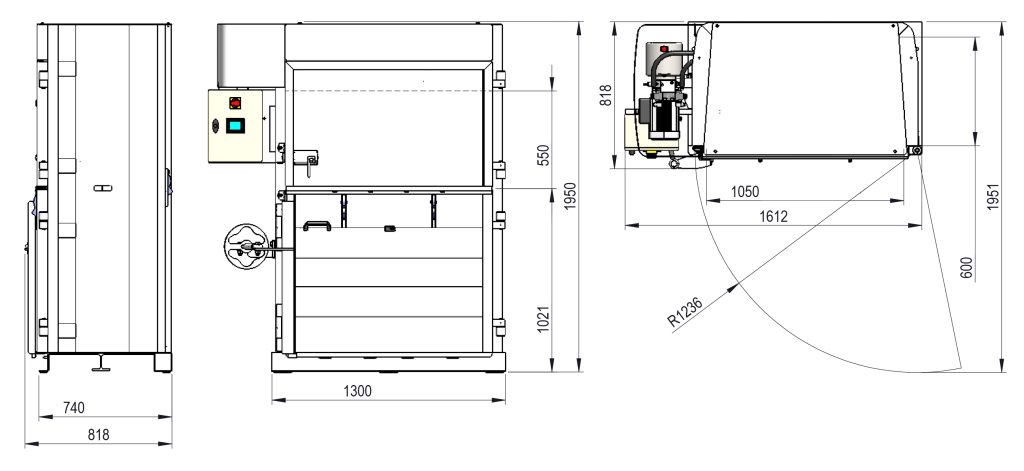

The 100 & 150 vertical balers are both relatively compact in design and due to the large filling opening are ideal to process larger sized products and volumes.

Both balers are suitable for processing cardboard, plastic film and other lightweight materials and include dual scissor action hydraulic cylinders, which reduces the overall baler height, whilst also delivering high compaction force. They produce a dense bale of approximately 100kg’s (SAM100) and 150kg’s (SAM150).

The relatively small foot print and low height required is ideal for those sites with limited height or space and this model incorporates state of the art and easy to use touch screen controls, making it easy to use for operators.

Installing a 100 or 150 vertical baler can deliver a range of financial, operational and environmental benefits for your business. A few more examples are as follows:

-

- Relatively small footprint

- Automatic cycle

- Low overall height

- Large filling opening for bulky materials

- Ideal loading height, ease of use for operators

- Single phase power (SAM 100)

- High compaction force

- Special product retention claws

- Unique and easy to use touch screen controls

- Easy access for strapping replacement

- Reduce storage space on site

- Reduce frequency of collections, reducing costs

- Create a potential new revenue stream for your business

- Easily processes cardboard, plastic film and other lightweight and bulky products into an efficient baled format